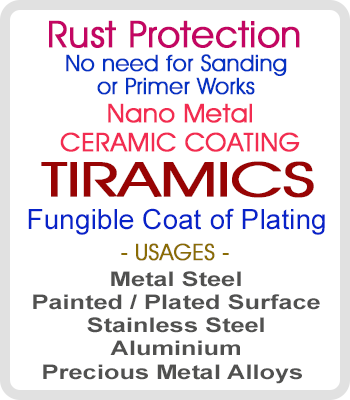

SeeUm Nano Metal "TIRAMICS" Ceramics Coating

SeeUm Nano Tiramics Coating for all kind of Steel, Plating, Paint, Aluminum, Bronze Surface

We have developed the world's first semi-permanent coating ceramics that can be coated directly on the surface without sanding or primer work.

"Tiramics" is a new metal ceramic coating with flexibility, elasticity and high hardness properties that complements the disadvantages of regular ceramic coatings.

These new properties make the painted surfaces not to be cracked in sheet metal forming process such as "90˚ ~180 ˚ bending", "rolling", "laser cutting

& marking", therefore you can do direct coat it on the original sheet state without any processing, and you can also cure the sheet coated simply.

The coated surface can protect the surface from scratching with hardness of pencil of over 7h ~ 9h.

It has rust prevention , high gloss, slippery property, water repellent, UV blocking effect, anti-corrosive characteristics

and prevents adhesion of contaminants such as fingerprints, you can also easy clean the surface.

It can be applied to various material surfaces such as clear coat of vehicle paint, metal steel, stainless steel and aluminum wheel & sash, steel saw, steel knife, etc..

:: KEY BENEFITS ::

* It can be coated directly on the surface without sanding or priming work before coating, so you can save the work time and cost,

* and it can display the beautiful texture and color of the original material sheet luxurious.

* It provides semi-permanent duration with features such as rust prevention, severe chemicals, moisture, climate change, color discoloration, corrosion protection,

anti-pollution and UV protection.

* It has a high pencil hardness of 7h~9h or more, it keeps the surface luxurious as like a new product with high protecting from scratches for a long time.

* Since the coated surface is elastic and ductile, cracks do not occur in plastic working such as bending, rolling, laser cutting and marking of 90~180 degrees,

so you can apply it on the plate state of raw material.

* Scratch proof / Rust Protection, High heat / electrical conductivity

* The slippery surface, water repellent effect, and self cleaning effect reduce dust and pollutants, thus reducing the frequency of frequent cleaning.

* No sticking of foreign substances, graffiti, fingerprints, etc..

* It can be easily removed contaminants such as calcium, grease and oil.

* Prevent the occurrences of salt, moss, green algae, etc.

* Bugs such as insects and flies do not stick well.

* It can be applied to a variety of applications such as car clear coat, paint surface, metal steel, stainless steel, aluminum.

* No more waxing products or polishes are required.

* A small amount of 10~15 ml is enough to coat 1 square meter, which is cost-effective.

:: CHEMICAL PROPERTIES ::

* Chemical Mixture : IPA dispersion, Multi-Hybrid, SiO, HSilicon Dioxide, Ethyl Silicate, etc.

* Color : Transparent

* Odor : Alcohol, Sour Odor.

* pH Value : 6.0~8.0 @20°C.

* Available Container : Any plastic bottle.

== HOW TO USE ==

:: PRE-TREATMENT ;::

+ Surface must be completely dried and cleaned.

+ Degrease with exclusive degreasing agent or ethanol, IPA.

+ If the surface is highly contaminated, clean it thoroughly with an alkaline detergent thoroughly

and remove the water using a high-pressure air gun or heater.

:: APPLICATION ;::

++ Applying Place : Dust free spraying booth ++

1. Application : Spray evenly on the surface using a low-pressure spray gun,

* Low volume low pressure (LVLP) spray guns also operate at a lower pressure (LP).

Spray Pressure : 1~2 Bar, Spray Distance : About 15~20cm, Consumption : 10~15ml / m2,

++ Curing Place : Dust free curing Oven ++

2. Heat Insulation Curing : Hour : 85°C : 1.5~2h | 120°C : 1h | 150°C : 0.5~1h. |

* After heat treatment, dry it at room temperature for 24 hours.

* After full curing, the thickness of a layer depends on the material and surface finish.

* Please clean the used spray gun with ethanol and IPA.

== TIRAMICS Technology Data ==

Items |

Specification |

Unit of Measure |

Remarks |

||||||||

Type |

1 Liquid Coating |

|

|

||||||||

Specific Gravity |

0.9 |

|

25°C |

||||||||

Color |

Transparent |

|

|

||||||||

Odor |

Alcohol, Slight Sour Odor |

|

|

||||||||

Dust Free Heat Insulation Curing |

Heat Tem. |

100 |

150 |

°C |

Car Paint Sample |

||||||

Hard drying |

1 ~ 1.5 |

0.5 ~ 1 |

hrs |

||||||||

Dry to touch |

10 |

5 |

Min. |

||||||||

Main Raw Materials |

Multi-Hybrid |

|

SiO2 |

||||||||

Pencil Hardness |

;6 ~ 9 |

h |

Aluminium (1T) |

||||||||

Glass (2T) |

|||||||||||

Galvanized steel sheet (1.6T) |

|||||||||||

SUS(0.5T) |

|||||||||||

Viscosity |

10 ~ 15 |

CPS |

| ||||||||

Surface Sanding |

Unnecessary |

|

Except in particular cases | ||||||||

Hydrophobicity |

Very Good |

Angle of water ≤ 110° |

|

||||||||

Non-Volatile |

15 |

% |

| ||||||||

Heat-Resisting |

550 |

°C |

| ||||||||

Storage Stability |

1 |

Year |

|

||||||||

Storage Temperature |

-10 ~ 10 |

°C |

| ||||||||

Coverage (Spray Coating) |

10 ~ 15 |

ml/m2 |

| ||||||||

Heavy Metals |

Non |

|

| ||||||||

UV Blocking |

Best |

|

| ||||||||

Application Method |

Spray, Blush, Roller, Printer |

|

Dust Free Spraying Booth | ||||||||

Use it when liquid is the same of room temperature |

|

||||||||||

Chemical Resistance |

Pass |

Salt Water(5%) |

1500 hrs | ||||||||

Calcium Chloride(5%) |

24 hrs | ||||||||||

Hydrochloric Acid(2%) | |||||||||||

Liquid Ammonia(2%) | |||||||||||

Ethanol(95%) | |||||||||||

Acid Detergent | |||||||||||

|

Alkali Detergent | |||||||||||

- Do not use thinner when degreasing.

- Do not work below 5℃.

- Do not mix the remaining liquid with the liquid storaged.

- Do not dilute with other products.

- Subdivide liquid as much as you use separately

- Wear protective equipment ( dust mask, safety goggles, protective glove, dustproof smocks) when you work.

::: CAUTIONS :::

- Be sure to follow the users instructions.

- Only use the product for its intended application.

- keep out of reach of children.

- Don’t drink and avoid eyes contact.

- If accidentally splashed in the eyes, flush immediately with water for at least 15 minutes.

- If accidentally swallowed, seek immediate medical attention by calling your local Poison Information Centre

::: STORAGE :::

Shelf Life : * Below -10℃ Freezing Storage : 1 Year / * 15℃ Room Tem. : 3 Months.

- Avoid direct sunlight.

- When it was stored in the freezer, thaw it at room temperature, and then use it at 15 ~ 30 ℃

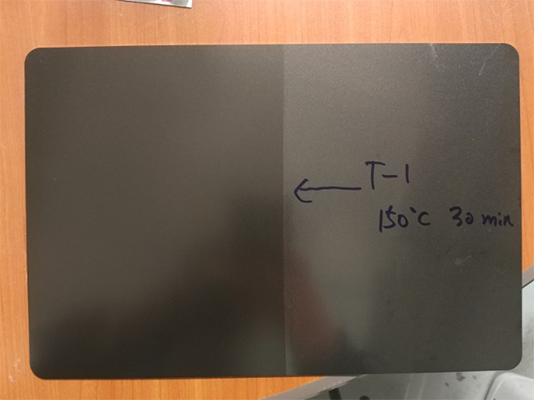

::: VIEW TIRAMICS PHOTOS :::

- Comparison with the coated side -

- Widely, Variety of applications-

::: VIEW TIRAMICS VIDEOS :::

+ Rust prevention test +

+ 9h Pencil Hardness Test on Aluminium sheet +

+ 9h Pencil Hardness Test on Stainless steel sheet +

+ Stainless steel working of Tiramics Test +

Have any question?